Global accelerator Fashion for Good has announced a new consortium backed by Kering and Adidas, among others, aimed at reducing water use in textile production.

The D(R)YE Factory of the Future is a new Fashion for Good effort that includes participation fromAdidas, Gucci parent, Kering, as well as PVH Corp., Arvind Limited, and Welspun India.

The initiative is directed at accelerating the fashion industry’s shift to dry textile processing—methods that use little to no water, produce no wastewater, and reduce overall energy use.

Fashion’s footprint

According to the World Economic Forum, the fashion industry produces 10 percent of all carbon emissions. It is the second largest water consuming industry. Fashion United reports that the fashion industry consumes at least 79 billion cubic meters of water per year—enough to fill 32 million Olympic-size swimming pools. The industry is also one of the biggest wastewater producers, accounting for 20 percent of global wastewater every year.

Fashion for Good’s D(R)YE Factory of the Future consortium features eight fashion and textile industry innovators aimed at reducing water use. Alchemie Technologies uses a digital technology to dye polyester and cotton fabrics that reduces water consumption; Eco2Dye converts carbon dioxide into a fluid form that can then be used to dye materials; Indigo Mill Designs uses a foam dyeing process that produces zero wastewater and minimal dye waste; Imogo developed a spray dyeing and finishing technology; Stony Creek Colors creates natural indigo that’s free of hazardous chemicals.

“Textile processing is the largest contributor to carbon emissions in the supply chain and a shift to mostly dry processing is crucial for the path to net-zero,” Katrin Ley, Fashion For Good’s managing director, said in a statement.

“Given the interdependencies in the processing stages, a stand-alone assessment of solutions is not sufficient. By validating a combination of technologies, we can unlock the full potential of those solutions. This is why this project is so pivotal,” she said.

“By validating a combination of technologies, we can unlock the full potential of those solutions. This is why this project is so pivotal.”

Water use

The effort comes at a critical time. According to projections from the Global Fashion Agenda and the Boston Consulting Group, water use is expected to increase by 50 percent by 2030. For the world’s leading textile producers—India and China—this poses significant threats as water scarcity is already significant. The severity is only expected to increase, seeing the shortfall between water supply and demand to reach 40 percent by 2030.

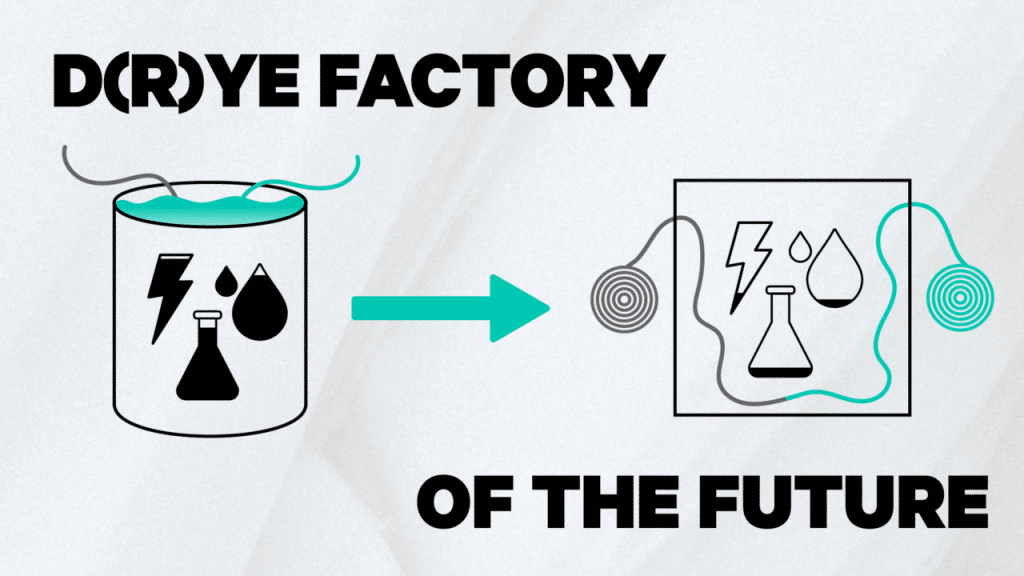

According to Fashion for Good, Tier 2 of the textile supply chain is where processing facilities turn raw materials into fabric. There, traditional pre-treatments, colouration and finishing, require large amounts of energy, heat, and water. This stage produces the highest amount of greenhouse gas emissions—52 percent—in addition to releasing large amounts of toxins into water.

The companies are specifically targeting pre-treatment and coloration in the Tier 2 stage, with attention toward denim, cotton, polyester, blends, and wool. If implemented industry-wide, the technologies hold the potential to reduce emissions at this level of production by up to 89 percent, and reduce water consumption by as much as 95 percent.

“One of the key levers to reduce impact is to move from wet processes—to mostly dry processes—innovative processing technologies that require very little to no water and reduced energy,” Fashion for Good says. This shift alone could reduce emissions by more than 25 percent for the entire fashion industry.

U.S. fashion label Ralph Lauren has been championing a move away from water-based dying and processing. Last year it launched its Color on Demand scheme, which would not only reduce the water used in the dyeing process itself, but allow stores to dye fabrics “on demand” at point of purchase, rather than before the items reach the stores. This would drastically reduce the amount of chemicals and water in the supply chain.

The D(R)YE Factory of the Future project also aims to leverage recent findings in its report entitled Unlocking the Trillion Dollar Fashion Decarbonisation Opportunity, which it co-authored with the Apparel Impact Institute. “The report charts a trajectory for the industry to meet its net-zero ambition breaking down the funding needed and maps integral levers across existing and innovative solutions,” Fashion for Good explains. “This report identifies that the shift from wet to mostly dry processing is crucial, with the potential to abate 24 percent of the industry’s carbon emissions and points out a set of interventions to unlock financing and accelerate the implementation.”

The project’s innovations will be evaluated with results published in a report later this year. The brand partners will work with Fashion For Good to integrate the novel tech and solutions into their manufacturing processes.