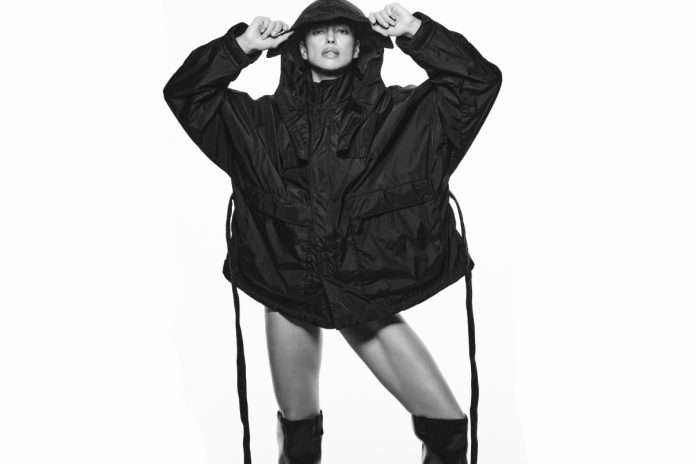

Global chemical company BASF, along with Zara parent company Inditex, have collaborated to create a groundbreaking sustainable jacket entirely made from nylon 6 derived from 100 percent textile waste.

The collaboration between BASF and Inditex highlights the potential for sustainable fashion and it also sets a new standard for the industry, showing that circularity and environmental responsibility can go hand-in-hand with fashion and style.

The new jacket is crafted using BASF’s innovative loopamid, a new type of polyamide 6. Nylon 6, also known as polycaprolactam, is a synthetic polymer and a type of polyamide. It’s part of the wider family of nylons, which are commonly used in the production of various textiles and plastic products. While nylon 6 has many industrial and consumer applications, its production and disposal pose significant environmental challenges. As a synthetic material derived from petrochemicals, it’s not biodegradable, contributing to plastic pollution. However, recent innovations, like the recycling and reuse of nylon 6, are aimed at reducing its environmental impact.

Every element of the new BASF/Zara jacket, including the fabric, buttons, filling, hook and loop, and zipper, is made from this sustainable nylon 6 material. The loopamid technology is a result of BASF’s “design for recycling” approach, ensuring that each component is not only eco-friendly but also maintains the same quality as virgin polyamide, with the added advantage of being recyclable multiple times.

Dr. Ramkumar Dhruva, President of BASF’s Monomers Division, expressed pride in the achievement. “BASF has reached an important milestone toward circularity in the fashion industry and pioneered an approach to close the loop for nylon textiles,” he said in a statement. “Our loopamid has the potential to revolutionize the PA6 market for the better. We are in the process of scaling up our technology to serve our customers with commercial quantities. The capsule jacket together with Inditex is the proof that circularity is possible, and we are eager to further drive the sustainable transformation of the textile industry.”

Inditex’s journey to create this sustainable garment involved collaboration with various fashion industry partners. These partners played vital roles in ensuring the viability of loopamid across the entire manufacturing process. ModaRe, a collection program, played a key role in providing the initial feedstock by classifying, sorting, and supplying discarded textiles. RadiciGroup was instrumental in transforming loopamid into yarns with different characteristics.

Additionally, companies like YKK and Velcro used loopamid in producing buttons, zippers, and hook-and-loop fasteners. Tessitura Vignetta, Freudenberg, and Gütermann were responsible for developing inner labels, filling, and threads for the jacket.

The process of creating loopamid begins with the chemical recycling of pre-used textiles. These textiles are broken down into caprolactam, a monomer liquid. This liquid is then purified and polymerized into polyamide 6 resin, which is subsequently spun into new fibers or materials.

Last summer, BASF partnered with biotech materials company Modern Meadow to develop an animal-free material. Dubbed “Bio-Vera,” that new material combines post-consumer waste and bio-renewable technologies, resulting in a novel material with a wide range of applications across fashion, automotive, and other consumer goods industries.

Related on Ethos: